Ipuleti Lensimbi Lomkhiqizi WaseShayina Elimelana Nesimo Sezulu Lokuhlobisa Isakhiwo

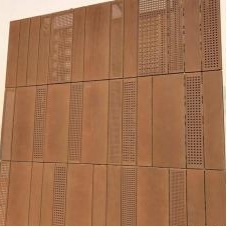

(1)Insimbi enesimo sezulu esiphezulu

Insimbi yesakhiwo sokumelana nesimo sezulu esiphezulu iwukwengeza inani elincane lethusi, i-phosphorus, i-chromium, ne-nickel ensimbi ukuze kwakhe ungqimba oluvikelayo ebusweni beqoqo lensimbi ukuze kuthuthukiswe ukusebenza kwensimbi ngokumelene nokugqwala komkhathi.Ungakwazi futhi ukwengeza inani elincane le-molybdenum, i-niobium, izakhi ezifana ne-vanadium, i-titanium ne-zirconium zingacwenga okusanhlamvu, zithuthukise izakhiwo zensimbi, zithuthukise amandla kanye nokuqina kwensimbi, zehlise izinga lokushisa lokuguquka eliphukayo, futhi zenze kube ukumelana kangcono nokuqhekeka kwe-brittle.

(2)Insimbi yesimo sezulu yesakhiwo esishiselwe

Izakhi ezengezwe ensimbi, ngaphandle kwe-phosphorus, ngokuyisisekelo zifana nensimbi yesakhiwo sokumelana nesimo sezulu esiphezulu, futhi inomsebenzi ofanayo nayo, futhi ithuthukisa ukusebenza kokushisela.

Ukusetshenziswa kwensimbi yesakhiwo sokumelana nesimo sezulu esiphezulu kungcono kunensimbi yokumelana nesimo sezulu yesakhiwo esishiselwe ngenxa yokumelana nokugqwala komkhathi.Isetshenziselwa ikakhulukazi ukubopha, i-riveting kanye nokushisela izingxenye zesakhiwo zezimoto, iziqukathi, izakhiwo, imibhoshongo nezinye izakhiwo.Uma isetshenziswa njengezingxenye zesakhiwo ezishiselwe, ubukhulu bensimbi akufanele bube bukhulu kuno-16mm.Insimbi engamelana nesimo sezulu yezakhiwo ezishiselwe inokusebenza okungcono kakhulu kokushisela kunensimbi yesakhiwo emelana nesimo sezulu esiphezulu, futhi isetshenziselwa kakhulu izingxenye zesakhiwo ezishiselwe amabhuloho, izakhiwo nezinye izakhiwo.

Qaphela: sinikeza insizakalo oyifisayo, wonke amashubhu ensimbi azohambisana nomklamo wakho wokuyikhiqiza.

| Izinga lokumelana nesimo sezulu kanye nenkomba yokusebenza | ||||||||||||||

| Ibanga Lensimbi | Okujwayelekile | Amandla Esivuno N/mm2 | Amandla Okuqina N/mm2 | Elongation % | ||||||||||

| Corten A | I-ASTM | ≥345 | ≥480 | ≥22 | ||||||||||

| Corten B | ≥345 | ≥480 | ≥22 | |||||||||||

| I-A588 G.A | ≥345 | ≥485 | ≥21 | |||||||||||

| I-A588 GR.B | ≥345 | ≥485 | ≥21 | |||||||||||

| A242 | ≥345 | ≥480 | ≥21 | |||||||||||

| I-S355J0W | EN | ≥355 | 490-630 | ≥27 | ||||||||||

| I-S355J0WP | ≥355 | 490-630 | ≥27 | |||||||||||

| I-S355J2W | ≥355 | 490-630 | ≥27 | |||||||||||

| I-S355J2WP | ≥355 | 490-630 | ≥27 | |||||||||||

| I-SPA-H | I-JIS | ≥355 | ≥490 | ≥21 | ||||||||||

| I-SPA-C | ≥355 | ≥490 | ≥21 | |||||||||||

| I-SMA400AW | ≥355 | ≥490 | ≥21 | |||||||||||

| 09CuPCrNi-A | GB | ≥345 | 490-630 | ≥22 | ||||||||||

| I-B480GNQR | ≥355 | ≥490 | ≥21 | |||||||||||

| Q355NH | ≥355 | ≥490 | ≥21 | |||||||||||

| Q355GNH | ≥355 | ≥490 | ≥21 | |||||||||||

| I-Q460NH | ≥355 | ≥490 | ≥21 | |||||||||||

| Corten | C% | Si% | Mn% | P% | S% | Ni% | Cr% | Cu% | ||||||

| ≤0.12 | 0.30-0,75 | 0.20-0,50 | 0.07-0.15 | ≤0.030 | ≤0.65 | 0.50-1.25 | 0.25-0,55 | |||||||

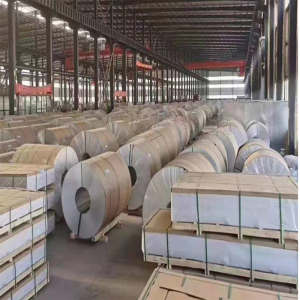

| Usayizi | ||||||||||||||

| Ubukhulu | 0.3mm-2mm(okubandayo okugoqiwe) | |||||||||||||

| Ububanzi | 2mm-50mm(hot rolled) | |||||||||||||

| Ubude | Ikhoyili noma njengoba udinga ubude | |||||||||||||

| Okuvamileusayizi | Ikhoyili:4/6/8/12*1500/1250/1800*Ubude(okwenziwe ngokwezifiso) | |||||||||||||

| Ipuleti:16/18/20/40*2200*10000/12000 | ||||||||||||||